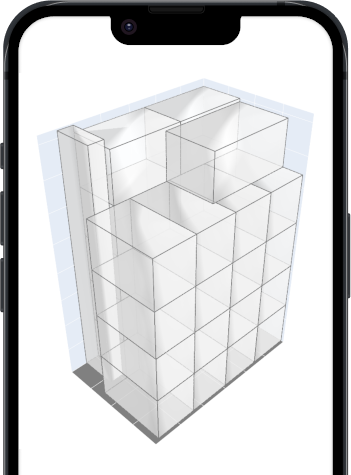

Scale your logistics, reduce costs, and lower your emissions by optimizing the space utilization of your shipping units.

Trusted for over 20 million packing calculations. Read our customer stories

The End-to-End Supply Chain

Manual packing decisions cost time, money, and space. Our API standardizes rules across all systems, delivering instant, optimized packing plans that reduce freight costs, emissions, and enable smart planning decissions.

"Managing dozens of box sizes and varying shipment requirements was chaotic. Our existing systems couldn’t make optimized decisions, so we relied on manual planning that slowed everything down."

A better workflow

Simple integration, affordable pricing, specialized packing solutions tailored for your business.

“Adding the Packing Optimizer API to our systems was seamless. It gave us niche functionality we were missing, helping us plan smarter and save on transport costs almost immediately."

{

"requiredNrOfBins": 3,

"totalVolumeUtil": 63.99,

"totalWeightUtil": 22.15,

"packedBins": [

{

"type": "small-box",

"maxVolume": 1.584,

"actualVolume": 0.90,

"actualVolumeUtil": 57.31,

"maxWeight": 1500,

"actualWeight": 1500,

"actualWeightUtil": 100,

"nrOfItems": 2,

"fittedItems": [

{

"id": "DTM001",

"xCoordinate": 0.5,

"yCoordinate": 0.6830,

"zCoordinate": 1.2

},

...A Modular Platform for Smarter Packing Across Industries

Digital Freight Matching System

In this implementation, the Packing Optimizer API is integrated to support a time-critical transportation service. Shipment requests are instantly evaluated, and the appropriate vehicle size is selected using precise packing calculations. This enables faster responses to customers while eliminating guesswork for planners. The result is a smarter, more responsive operation that fully supports time-critical logistics.

Concept To Commercialization

The team uses the Packing Optimizer API to evaluate packaging designs with precise space and fit calculations. This allows engineers to test concepts quickly, compare alternatives, and identify material and cost efficiencies early in the design process. With faster, evidence-based insights, the team can create packaging solutions that are more efficient, more protective, and better aligned with customer requirements.

Smarter Shipping Starts at Checkout

The team at this e-commerce company uses the Packing Optimizer API to automatically select the best-fitting box as customers place orders on their website. The API evaluates item dimensions in real time and recommends the most efficient packaging option for every checkout. This reduces wasted space, lowers shipping costs, and ensures a consistent packing process in the warehouse, keeping fulfillment lean, fast, and sustainable.

Multi-Step Packing: Cylinder to Box to Pallet

In this use case, the Packing Optimizer API is used to pack cylinder items efficiently into boxes and then arrange those boxes on pallets. With a large variety of box sizes, the API identifies the best combinations to maximize space and ensure each cylinder fits securely. This multi-step optimization streamlines complex packing challenges, reduces material waste, and makes full use of available packaging options. The result is precise, reliable packing from cylinder to box to pallet every time.

Packing Optimizer empowers businesses of all sizes to leverage the same cutting-edge optimization techniques used by industry leaders. By providing access to advanced optimization technology, we aim to support users in achieving global emission reduction goals while driving their business success to new heights.

Start using the Packing Optimizer API to improve decisions from order to delivery.